Thanks to their corrosion resistance and purity, cromox® chains are ideally suited for use in clean rooms, in the food industry, in the chemical and pharmaceutical industries, as well as in particularly aggressive environments that are prone to corrosion (e.g. in offshore applications, when used in chemicals, alkalis and their vapors, and many more).

Wherever the highest requirements have to be met in the industrial environment when lifting and moving loads and corrosion resistance is required, our cromox® sling systems are used. Our industrial chains for lifting equipment are characterized by the use of outstanding stainless steel* or duplex alloys. Our high quality products with corresponding grades offer you safe handling as well as highest load capacity and reliability in each of your applications.

*stainless steel or inox, from French "inoxydable", in English "inoxydable" or "non-corrosive"

cromox® stainless steel (inox steel) chains convince with their long-lasting corrosion resistance, high strength values and load capacities. This makes them true all-rounders for a wide variety of applications in food processing plants, in the chemical industry or even in the medical sector. Thanks to their material grades, our chains are suitable for use in corrosive seawater, saline solutions, wastewater, alkalis and acids.

Rely on tested cromox® hoist chains and benefit from advantages such as high dimensional accuracy and tight tolerances for optimal chain run. Our industrial chains for hoists are characterized by the use of outstanding stainless steel or duplex alloys. With our hoist chains you get the ideal solution for motorized and manual hoists.

Whether recycling, bulk materials or steel industry – our conveyor chains convince under the toughest operating conditions with their robust properties and durability. In addition, our high-quality conveyor chains made of stainless steel are also used in the food and automotive industries. What are your requirements? Talk to us – we will develop the conveyor chain individually for your application.

The stainless steel loop welded chain slings are welded wreath chains without transition link for lifting loads. Thanks to the high quality stainless steels, our loop chains can be used in corrosive environments and aggressive environmental conditions. For example, we also achieve very high acid resistance through appropriate processing (such as electropolishing) of our stainless steels, so the loop chains can be used in demanding environments, among others.

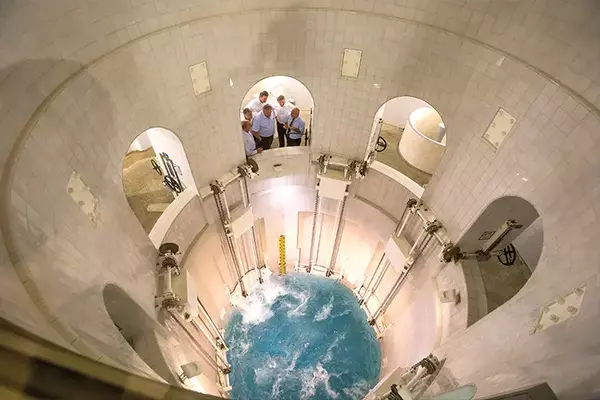

Our cromox® pump lifting chains made of high-quality stainless steel are specially designed for use in water extraction in sewage treatment plants and in well construction at waterworks. For gradual lowering or lifting of pumps and aeration equipment, the stainless chains made of high-strength stainless steel AISI 316L and AISI 318LN Duplex have enlarged suspension links at the beginning of the chain, at segment intervals and at the end. For special requirements, we also manufacture individual pump chains for your application.

Corrosion resistance contributes to longevity and ensures functionality in demanding environments. Harmful elements such as moisture, salt and chemicals can affect the material strength of the chain links and lead to premature discard. Critical to corrosion resistance is the selection of the proper material and finish or processing. Stainless steel and certain alloys or treatments such as electropolishing offer excellent solutions here. They also reduce maintenance and the associated costs. Corrosion-resistant chains are ideal for applications in demanding industrial sectors such as heavy industry, marine transport or the chemical industry. Investing in corrosion-resistant chain solutions pays off in many ways because they reduce operating costs and increase productivity.

Quality is a decisive factor for us as a manufacturer of stainless steel chains. This begins with the purchase of the high-quality stainless steel, which must meet high standards. The manufacturing and processing process itself is equally important. State-of-the-art technology is used here to ensure optimum performance and durability of the chains. Continuous quality checks during and after production are essential, as is testing of the chains in the company's own Lloyd's Register-certified testing laboratory. Certifications by independent testing institutions can additionally confirm the quality. Finally, customer service is another aspect that must not be neglected. After all, good service also contributes to overall quality and strengthens customers' trust in the manufacturer.

Stainless steel chains belong to the link chains, where the links are joined directly into each other. They are used for lifting, conveying and lashing.

Chain made of stainless steel is rustproof and offers the following advantages:

Grades for round steel link chains play a decisive role in safety and reliability. The Grade 60/Grade 60+ used for cromox® chains are characterized by the highest quality. Their advantages are excellent strength and increased load capacity compared to lower grades. These chains are ideal for demanding applications where safety and load capacity are of paramount importance.

Our cromox® chain solutions are completely "Made in Germany", quality-tested in our own test laboratory and meet all common standards and quality classes depending on the application, for example analogous to DIN 766 / 5684 / 5687. In addition, with our engineering and materials expertise, we develop application-specific sling systems for you - precisely according to your specifications and intended use.

Member of:

Contact us for information or a quote